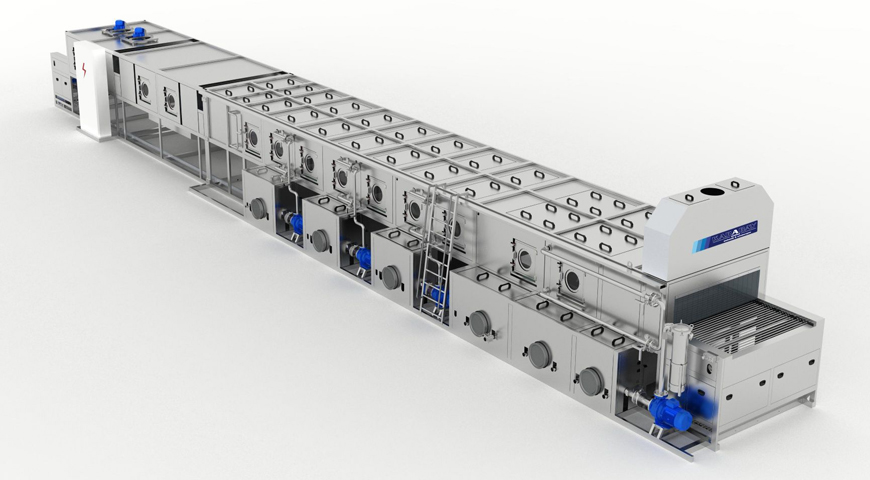

Tunnel Type Conveyor Belt Washing Machine Features

In tunnel type conveyor washing machines, the mode of transport can be suspended or belted depending on the geometry of the part to be washed. After the products to be washed are placed on the moving conveyor in the entrance area, they pass through washing, rust removal, rinsing, passivation (protection against rust) and drying processes, respectively, and reach the exit section. Imported nozzles made of AISI304/316 quality stainless steel are used to clean every point of the materials equally and effectively from the top, bottom and sides. The conveyor belt, which is specially designed according to the materials to be processed, is manufactured from 304 or 316 quality stainless steel to provide the highest carrying capacity. The speed of the conveyor can be adjusted by digital speed controllers. Imported stainless steel pumps resistant to 95 °C are used in the circulation system. The heating system can optionally be electric, with a heat exchanger or with a burner. Boilers are covered with insulating materials to save energy. In our systems with PLC, the entire plant is controlled from the operator panel. There are automatic water feeding, liquid level control, conveyor safety clutch and safety measures in accordance with the standards, which are standard in each of our machines. With automatic dosing, desired tank concentrations can be kept constant. Areas of Usage: It is used for oil, sawdust and surface cleaning of parts with high production speed or high number or surface preparation before painting. Especially: Automotive, Coating, Food and Metal Processing Sector.